About the Ong Lab

The Ong Lab focuses on the development of new sensors and devices for medical applications, with emphasis on regenerative medicine for orthopedic care.

Currently, we are deploying magnetoelastic materials, which are commonly used for making acoustic speakers or anti-theft tags, as implantable devices. We use the actuating and sensing abilities of this material to create internal bone fixation plates that can monitor the healing conditions and provide mechanical loads to maximize bone regeneration. Another example of our work is the ongoing development of a new sensor system that can continuously track the microenvironment of cells in a bioreactor. In addition, we are actively engaged in the deployments of various wireless sensor technologies for other medical applications and environmental monitoring.

We are always looking for partnerships within and outside of the university to amplify the impact of our sensor research. Please contact us if you are interested in our work and want to know more. We are also expanding our lab and are seeking motivated researchers (post-doctoral researchers, engineers, graduate and undergraduate students) to join our team. Please contact Ong (kgong@uoregon.edu) if you are interested.

The magnetoelastic internal bone fixation plate for investigating the effectiveness of localized high-frequency mechanical loading on the regeneration of a rodent’s femur critical size defect.

A magnetoelastic embedded sensor for measuring pressure within a blood vessel. The same sensor can be adapted for monitoring pressures in other sealed or hard-to-reach areas.

The circuitry of the implantable Bluetooth transceiver for monitoring strain at a rodent’s femur fixation plate. With additional sensor modules, this sensor platform can be upgraded to monitor other physical and chemical parameters.

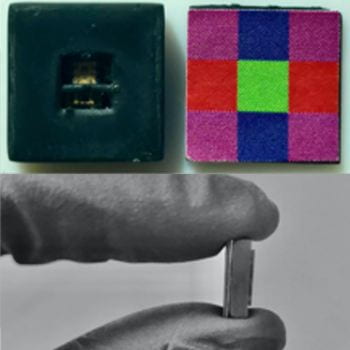

A multi-axial shear stress sensor for orthopedic applications. The sensor measures shear stress and strain based on optical coupling red, green, and blue light emitted by an LED, reflected off a color pattern, and measured via a photodiode. A tunable PDMS layer gives the sensor structural elasticity and allows for the measurement of both shear strain and stress.